PRODUCT

MoyaVox is not just Voice Picking. Whether you are an e-fulfilment business, a food and beverage retailer or a manufacturing plant, MoyaVox can add an additional level of control and reporting all of your warehouse processes.

RECEIVING

Ensuring the accuracy of the receiving process is the building block for all warehouse processes, and with MoyaVox you can ensure that the goods received match the order that was placed. Human error is removed by the use of blind checks, and the stocks integrity is confirmed before it is put into your locations.

PUT-AWAY / STOCKING / REPLENISHMENT

Having a flexible and efficient put-away process allows you to make the best use of your operators and their Materials Handling Equipment (MHE). Working with the replenishment function, operators can have their work prioritised automatically, interleaving between the two functions.

CASE PICKING

MoyaVox can make your case pickers more efficient and accurate. While having their eyes free to look at what is occurring ahead of them, you will likely see a reduction in accidents.

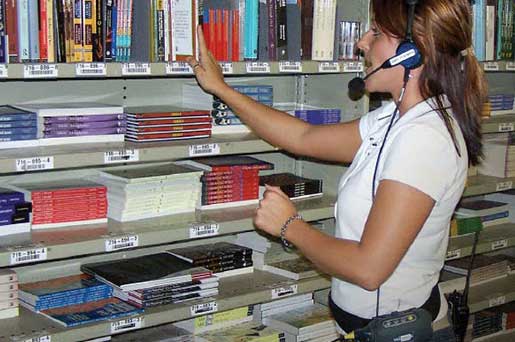

PIECE PICKING

The benefits from using the MoyaVox solution in piece picking are quick and easy to realise. Taking control of the operators and ensuring they follow the best available process, while also catching and actioning any exceptions, ensures that we typically see 25% efficiency improvements against existing RF Scanning solutions.

PICK TO TOTE

When your workers become hands-free, eyes-free in a Pick to Tote roller environment, you can increase both their efficiency and accuracy, whilst having accurate tracking of each individuals performance results, gaining a valuable insight on individual worker performance.

CAROUSEL PICKING

Using MoyaVox to run your carousel operation allows your operators to handle the hanging items without having to pause and refer to a screen or a piece of paper. This increases the speed and accuracy while allowing your operators to work continuously.

BATCH PICKING

Picking multiple orders to a cage or cart is made easy with the MoyaVox solution. The system ensures accuracy and tracking, allowing your business to have confidence when picking for a mix of customers.

CAGE, TROLLEY OR PICKING TRUCK

These are made easy with a MoyaVox solution. The picker is allowed to work as fast as possible while maintaining their accuracy. Having a wearable device ensures they can control their cage, trolley or picking truck at all times while still receiving the relevant instructions from the headset, allowing their journey between locations to be safe and controlled.

IN THE FREEZER

A MoyaVox solution works equally well in a freezer environment. Our Honeywell Vocollect Solutions devices and batteries are tested and rated to support more than a full shift in extreme conditions. With no requirement to input data through a keyboard, or to read information from a screen, the operator has no issue with protective clothing or condensation building up on the screen.

PUT-TO-STORE / FLOW-THROUGH

MoyaVox can speed and track workers using put-to-store and flow-through staging to break pallets or cases into store level orders without storing the incoming products.

CROSS-DOCKING

You can use MoyaVox to consolidate shipments from disparate sources and realise economies of scale in outbound transportation. The integral scanner on the A730 can be used to capture certain data while the operator still achieves the increased efficiency and accuracy of a Voice Directed process.

SUPPORTING NARROW AISLE & HIGH REACH TRUCKS

With MoyaVox we enable the operator, not the vehicle. This means that narrow aisle, counter balance and high reach vehicles can be used by the same operator with ease. Each qualified operator can carry out their designated function on any appropriate vehicle.

INTERNET STORE & PACKING STATIONS

Using the MoyaVox packing application, you reduce the number of steps required to pack an order and increase the accuracy and efficiency.

CYCLE-COUNTING & PHYSICAL INVENTORY

You can either carry out a dedicated stock check, or use your pickers or other operators to carry out controlled stock checks at any location.

PRODUCT TRACEABILITY

Different items may require additional data, be that pharmaceutical, perishable or high value items. MoyaVox can accurately and easily capture this, including dates, batch, weight, serial number, and any other relevant data.

LOADING

Whether you are loading pallets or cages, MoyaVox can drive your process. Allowing shift supervisors to assign additional workers to a time sensitive load, or changing the priority of the scheduled loads to fit a changing requirement, this is standard functionality that can be invaluable to the business.

MANAGEMENT FUNCTIONS

With MoyaVox you can manage shifts, teams or individual workers. You have the ability to split picks, change the priority of warehouse assignments in real-time, re-task operators as the situation changes and configure routes, marshalling areas, and bays. With the easy to export, custom reports, you can export your Key Performance Indicators (KPI) at the click of a button.

This is all possible without upgrading or replacing your current Warehouse Management Solution.

Want To Discover How Moyavox Voice Picking Technology Can Help Your Business?

OUR PARTNERS

Moyavox | 3 Sherbrook House, Swan Mews, Lichfield, Staffordshire, WS13 6TU | Telephone 01827 55334

© Copyright Minster Computer Systems Ltd 2023 | Registered in England No: 2271395 | VAT Registration Number: 486806795